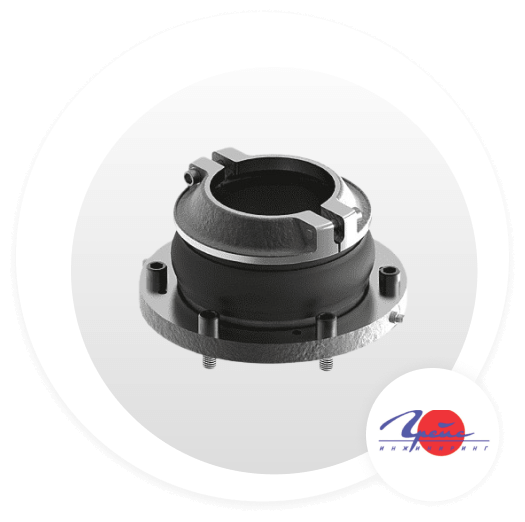

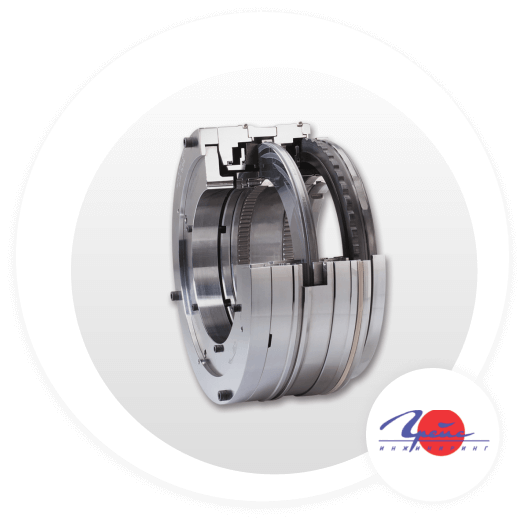

We offer you the most effective solution for all the mentioned problems – Dry Gas Seal Systems (DGS). DGS systems are the most popular turbine shaft seals. They can be used for almost all kinds of equipment where there is a necessity to seal rotating shafts usage is predetermined by the vast range of economic and ecological advantages comparing with traditional systems of shaft end seals:

We understand that rotating equipment, such as compressors, is highly dependent on reliable Dry Gas Seal (DGS) solutions for safe and efficient operation. Hence, at Mascot Dynamics, we only supply dry gas seals suitable for all kinds of equipment where there is a necessity to seal rotating shafts