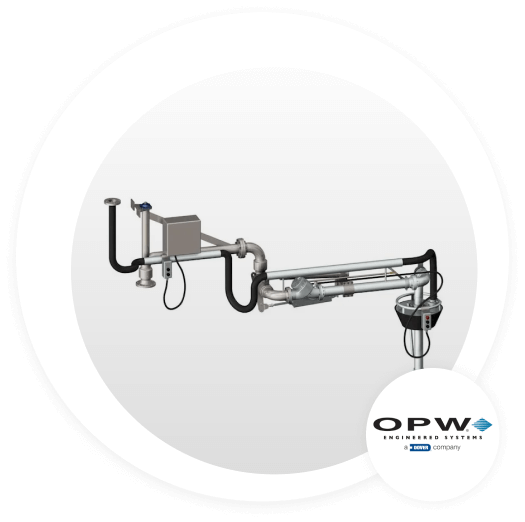

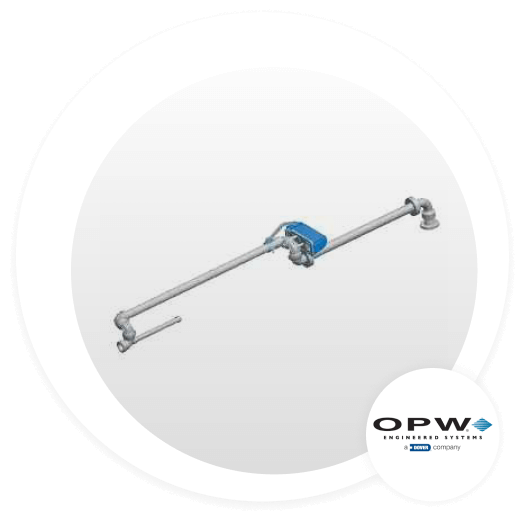

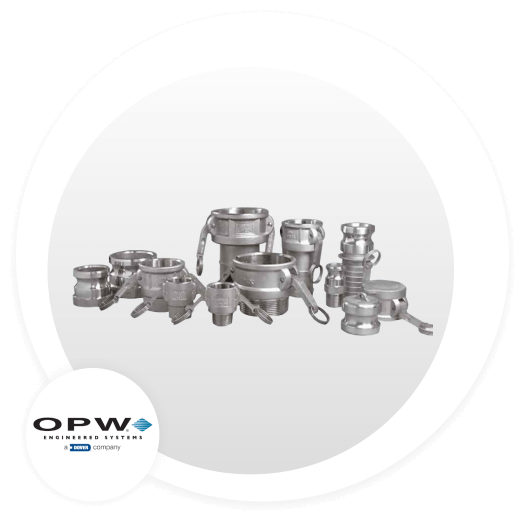

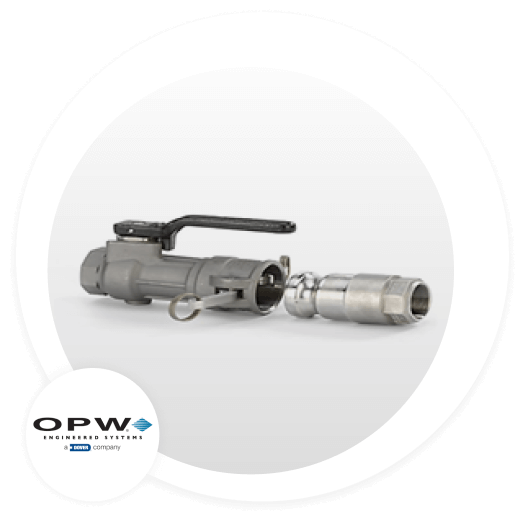

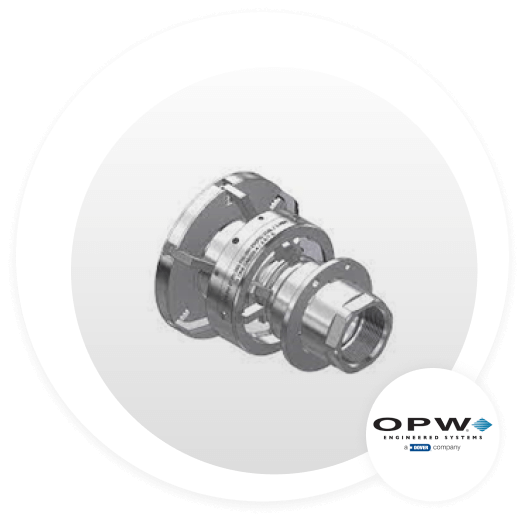

OPW Engineered Systems, part of the OPW Fluid Transfer Group, provides expert solutions for the safe handling, transfer, monitoring, measuring and protection of hazardous bulk products worldwide.OPW Engineered Systems specializes in the engineering, designing and manufacturing of systems for the safe and efficient loading and unloading of critical hazardous materials

Benefits and Features

Benefits

Benefits

Benefits and Features

Benefits

Benefits

Benefits

Mascot Dynamics supplies OPW Engineered Systems products in India.OPW Engineered Systems, part of the OPW Fluid Transfer Group, provides expert solutions for the safe handling, transfer, monitoring, measuring, and protection of hazardous bulk products worldwide.OPW Engineered Systems specializes in the engineering, designing, and manufacturing of systems for the safe and efficient loading and unloading of critical hazardous materials